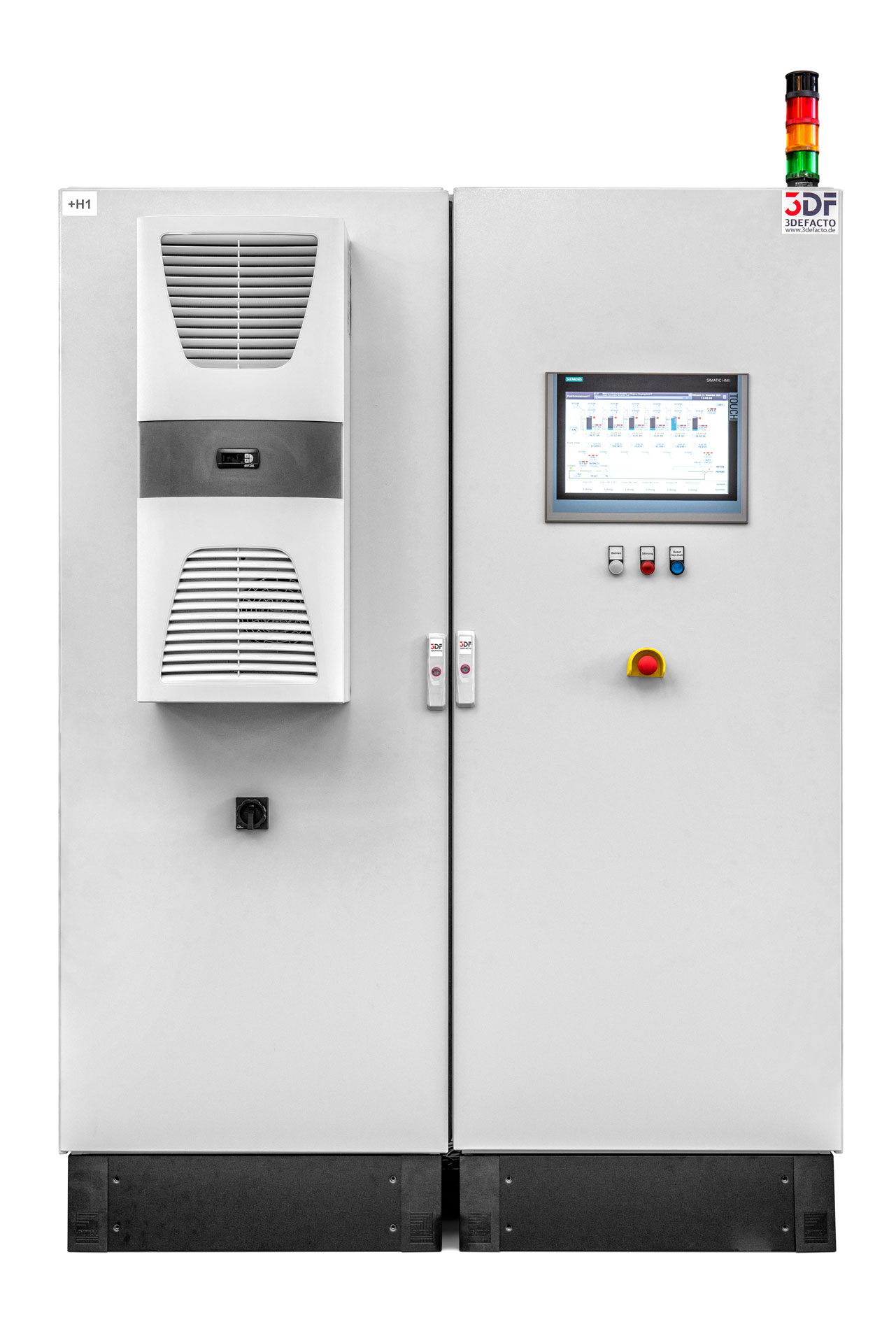

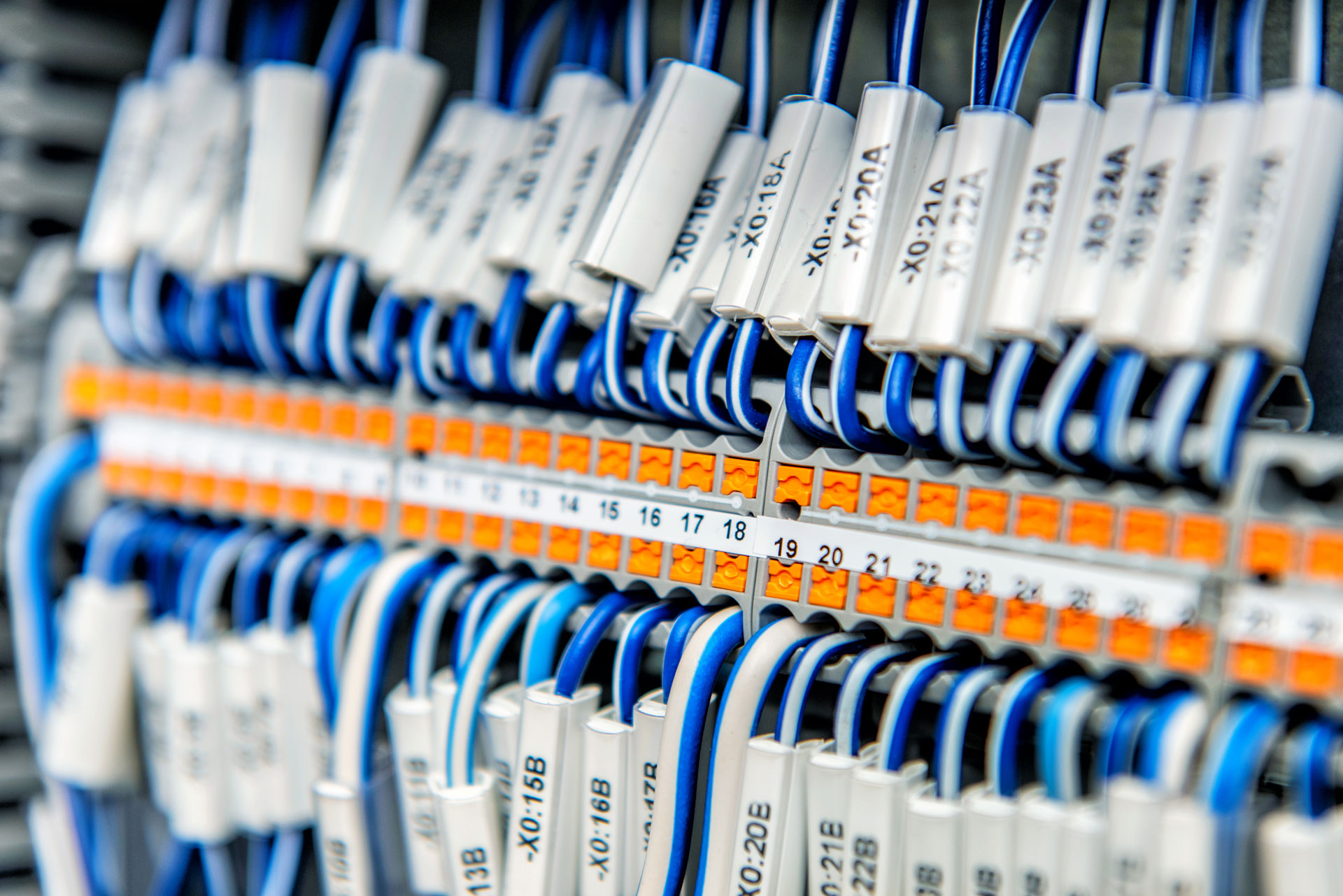

Mixing stations from 3defacto are planned and manufactured according to your requirements in order to realize the optimal solution for you. 3defacto offers dosing stations for solid and liquid raw materials. In both cases the station includes the emptying of the raw material containers, the storage of the raw materials as well as their dosing and mixing.

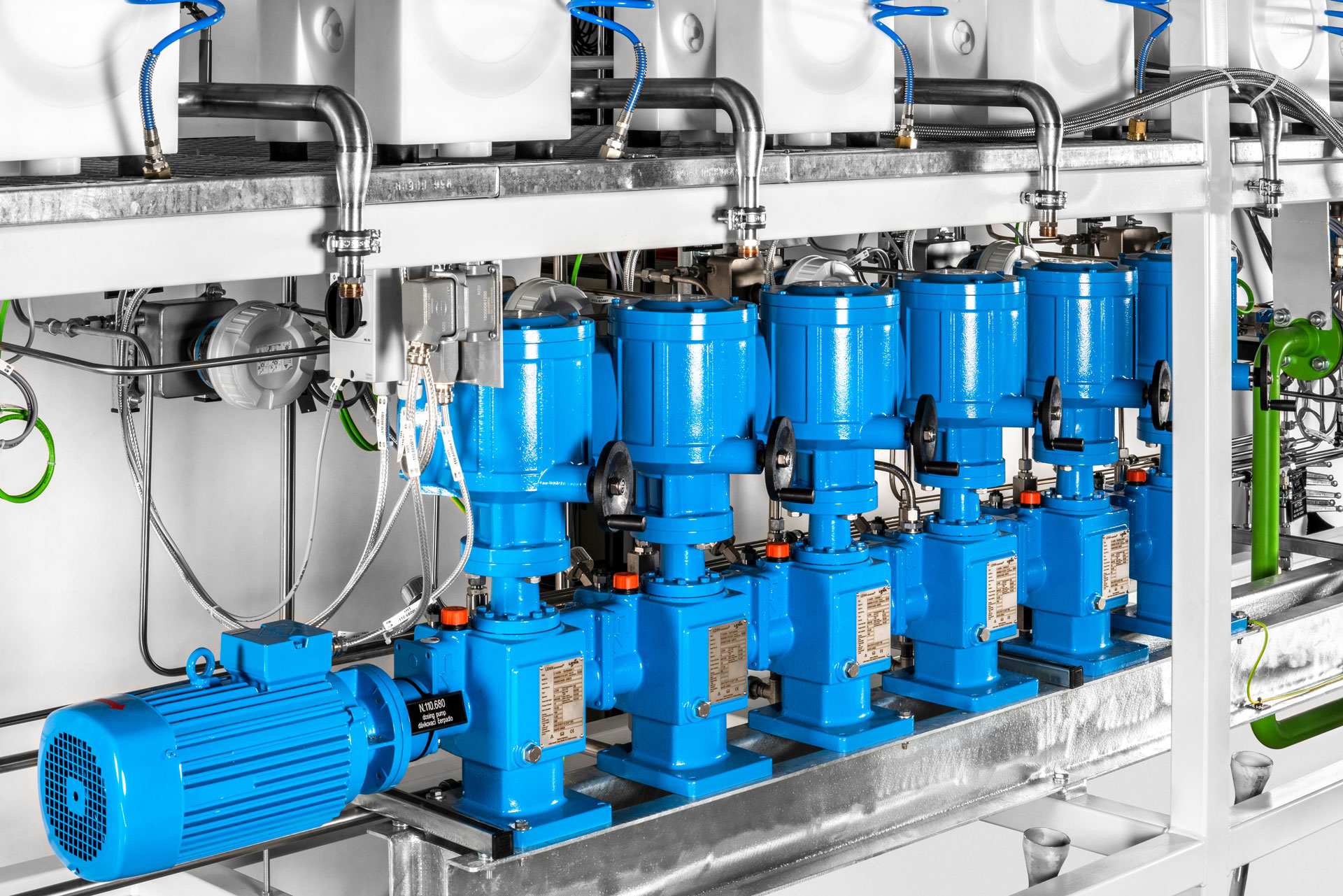

In our liquid dosing stations, compressed air diaphragm pumps transfer the raw materials from their containers into individually designed storage tanks. Depending on the requirements, the containers can also be cooled. The raw materials are removed via the dosing pump, which doses the individual components according to the stored recipe. Once dosing is complete, the mixture is homogenised with a stand mixer. Optionally, the dosing station can also be connected directly to the reactor. Small transport containers or mobile containers for larger quantities are available as receiving containers. Most dosing and mixing stations also have conditioning stations, an NDI station and a cleaning station.

Your advantages with a dosing and mixing station from 3defacto:

- Flexible number and size of storage tanks

- Cooling of the storage tanks

- Fully automatic dosing

- Various recipes