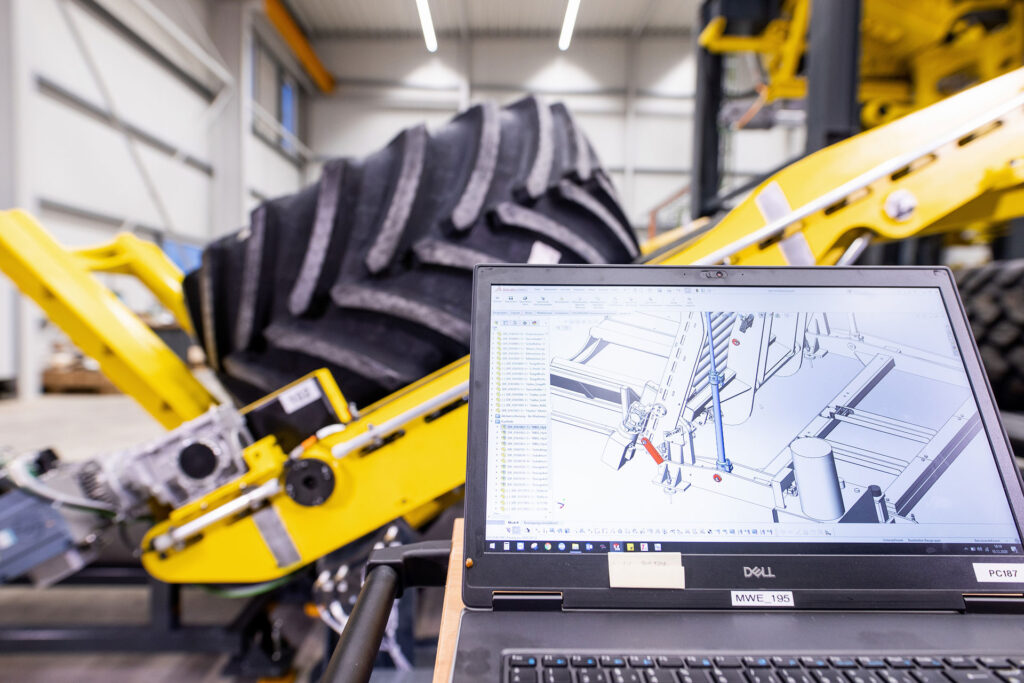

The fully automatic tyre-mounting machine from 3defacto is a groundbreaking innovation in this field. The machine operator takes care of feeding the tyres and rims onto the infeed conveyors, the machine recognises the tyre size and controls the subsequent modules fully automatically.

In this way, tyre sizes from 20-58 inches can be mounted automatically and inflated via a filling bell. 3defacto guarantees a filling tolerance of +/- 0.1 bar at filling pressures of up to 9 bar.

The assembly of the different tyre sizes without the need for resetting makes this innovative system unique.

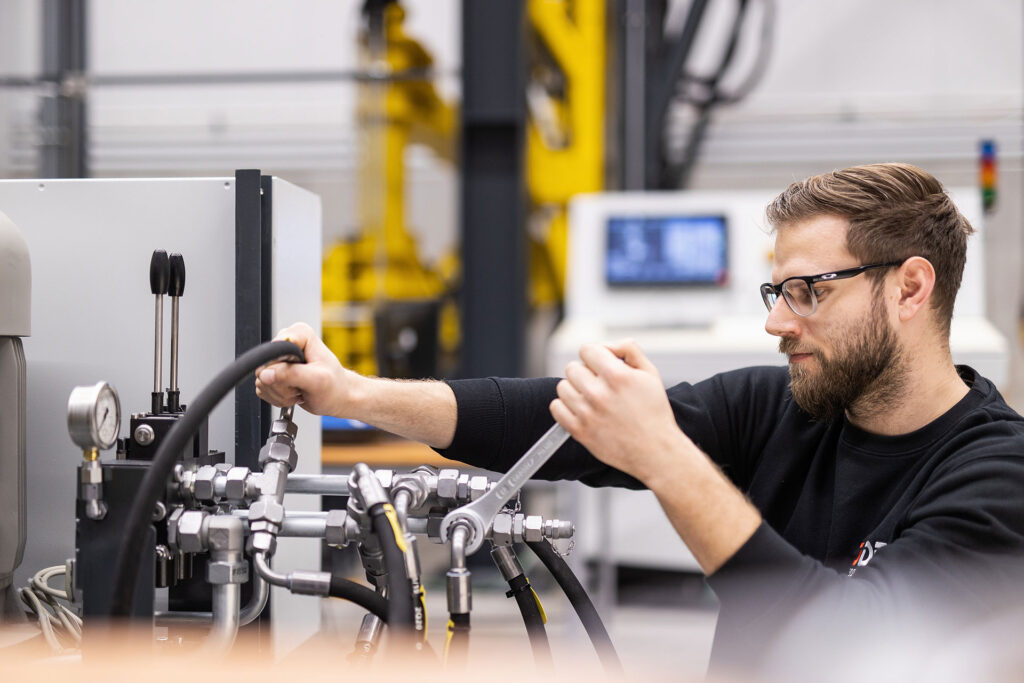

The system is designed and built according to the customer’s requirements, commissioned in our factory, and installed at the customer’s location only after successful pre-acceptance. All services, starting with design, manufacturing, hydraulic design, electrical planning and software, are provided by our company.

Modules of our system

With our modular design, we find the right solution for every challenge: from individual optimization recommendations to the implementation of complex systems. 3defacto’s wheel assembly ensures an economical, energy-saving and optimized production of wheels at your site.

Our plants are designed and built according to the customer’s requirements, commissioned in our factory and installed in the customer’s plant only after successful pre-acceptance. All services from design, manufacturing, hydraulic design, electrical design and software are provided by our company. All that remains to be done on site is to assemble, connect and commission the system.

The wheel plant can be divided into several independent modules:

- Conveyors for wheel assembly

- Tire soaps

- Assembly station

- Pumping station

- Measuring stations

- Laser marking

- Stacking crane with rotating grab

For more detailed information on these modules, please refer to the respective product description.

Advantages of the 3defacto system for wheel assembly:

- Produce a high-quality end product without damage

- Very fast installation and commissioning due to modular design

- Flexible system configuration

- Extensive experience in wheel assembly

We are happy to answer your questions, please just contact us!