Are you looking to invest in a new plant for processing PUR high-performance elastomers? Then you have come to the right place. We take care of all steps, from planning to detailed design, production, assembly, and commissioning of the plant, we take care of all the work steps. This makes it easy for us to respond to your individual requirements and consider specific conditions.

Prepolymer production process

Our prepolymer plants are suitable to produce polyurethane, a plastic. Depending on the manufacturing process, the end product has different properties, such as shore hardness, elasticity, wear resistance or temperature resistance. Our prepolymer plants process raw materials such as polyol, isocyanate in the form of NDI or MDI, and crosslinking agents to produce an elastomer. We develop tailor-made solutions for prepolymer production, whether the flake-like solid NDI or the of the liquid MDI is used.

Reactor of the prepolymer plants

In the heart of the plant, the prepolymer reactor, the various raw materials are mixed into a homogeneous mass: polyol, NDI or MDI and additives. This is preceded by the fully automated metering system. It ensures that all the materials enter the reactor in exactly the right quantities.

The dosing and mixing process can include up to 20 process steps. Any number of recipes can be stored, ensuring the right mixture for each high-performance PUR polymer to be produced. The result: a wide range of end products.

We attach great importance to operational security. This is ensured by different password levels. An example: The plant operator can start a new batch, or the shift supervisor can select a different recipe.

The reaction process determines the quality of the product. The exact mixing ratio of the raw materials and the temperature control are important. We control these factors. The optimal surface ratio of your reactor ensures precise and rapid temperature control. The status of the reaction process can be monitored in real time. The advantage: the optimal time for further processing of the prepolymer can be determined immediately. We have also thought about cleaning – it is easy and efficient.

More modules of our plants

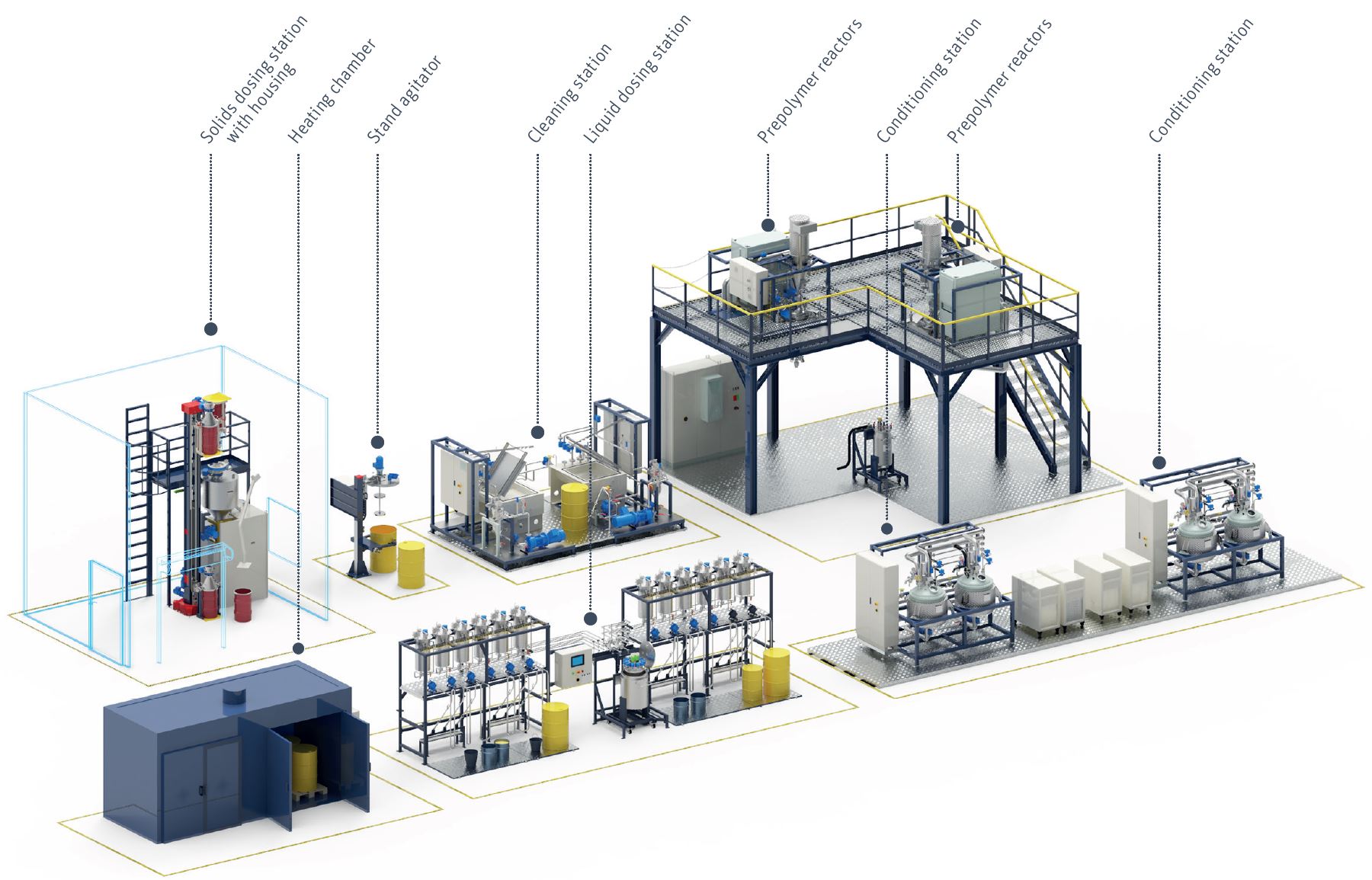

With our modular design, we find the right solution for every challenge: from individual optimization recommendations to the implementation of complex systems. 3 defacto’s plant technology offers you an economical, energy-saving, and optimized production for prepolymer manufacturing. The numerous successfully implemented projects at our customers‘ sites proves that this concept works.

All modules, including the control cabinet, are completely built in our halls – including all connections – such as for the compressed air or vacuum supply. We install all components inside the steel structure. This ensures that they will survive transport to you without damage. Before we deliver the plant to you, we first test the modules and connections at our premises. Then, all that remains is to assemble, connect and commission the system at your site.

You can combine the reactor with further modules

- Dosing station for solids and liquids

- Conditioning station for liquid media

- Heating chambers

- Cleaning station

- Container unloading station

For more detailed information regarding these modules, please see our product description.

Advantages of 3defacto prepolymer plants

- Production of high-quality elastomeres

- Very fast installation and go-live

- Flexible system configuration

- Extensive experience in the field of prepolymer production

We are pleased to answer further questions. Please Don’t hesitate to contact us!